Science

-

6 years ago

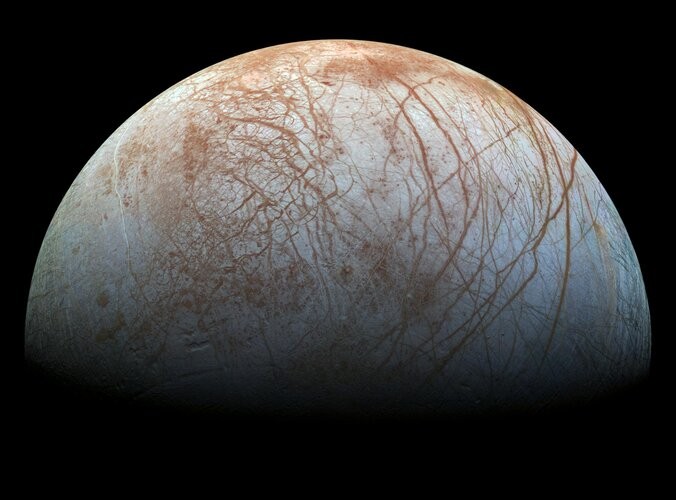

Electrochemical cell could split the Moon's frozen water into rocket fuel

MinesNewsRoomMechanical Engineering's Greg Jackson is collaborating with OxEon Energy on a $1.8 million NASA project that could bring interplanetary fuel stations one step closer to reality. The analogy the space resources field likes to use goes a little like this: If you were going on a cross-country road trip, you wouldn’t bring all the gasoline your car needed with you. You’d fill up at gas stations along the way. In the future, the same will go for space travel – except instead of gasoline, you could fill up on rocket fuel derived from the frozen water known to exist on the Moon. “The idea of getting rocket fuel from the Moon is a game changer for NASA,” said Gregory Jackson, professor of mechanical engineering. “If you have to launch everything from Earth, that geometrically grows the amount of fuel you need – you need fuel just to get the fuel out of Earth’s gravity well. “If you could refuel and launch from the Moon or from a space station between the Earth and Moon, you would greatly reduce the energy requirements to get to Mars or beyond, and therefore save costs and possibly reduce mission time.” Jackson is leading a team of Colorado School of Mines researchers, including Chris Dreyer and George Sowers of the Center for Space Resources, that is contributing to a $1.8 million NASA project that could bring those interplanetary fuel stations one step closer to reality. OxEon's electrochemical stack for splitting carbon dioxide on Mars will be modified for high-pressure water-splitting.Courtesy of OxEonIn partnership with OxEon Energy, the team is developing a solid-oxide electrolysis system capable of processing the frozen water near the Moon’s poles into liquid hydrogen and oxygen – the most effective rocket propellant known to man. And just as important, the system will have to work while withstanding the harsh environments of the permanently shadowed craters of the moon where the ice is found. “OxEon has developed a robust electrochemical cell that can split water at elevated pressures. Their cell works at about 700 to 800 degrees Celsius and we’re trying to enable it work in environments that are well below zero,” Jackson said. “We need to build a system that can take the ice, melt it, split the water and internally recover all the heat to minimize the energy that is needed from outside. We can’t afford to waste any energy when on the Moon.” “Well below zero” may be a slight understatement. In the permanently shadowed regions of the Moon where water ice has been discovered, the temperature can be as low as -230 degrees Celsius. The Mines team is focused on the design work needed to ensure efficient operation of the system in these super-low temperature conditions, Jackson said. To assess this, the team will test a subscale demonstration system on the Mines campus, in the low-temperature vacuum chamber in the Center for Space Resources. Based in Salt Lake City, OxEon Energy is no stranger to the demands of deep space applications, having also played a vital role in the development of a system for producing oxygen from carbon dioxide on Mars. MOXIE, the Mars Oxygen ISRU (In Situ Resource Utilization) Experiment, will be one of seven instruments aboard NASA’s 2020 Mars mission. “OxEon Energy is looking forward to working with the staff at Colorado School of Mines,” said Lyman Frost, CEO of OxEon Energy. “OxEon is aware of the excellent reputation of Mines and its researchers. The challenges of deploying a system that can work under the extreme physical constraints of a rocket launch/landing and the lunar environment can only be met by closely integrating the technical capabilities of both entities.” The high-temperature electrolysis being developed by OxEon for this project also has applications for producing fuel on Earth, enabling the use of renewable energy to produce transportation fuels as drop-in replacements for fossil fuels.

Read More -

6 years ago

Mines ranked in top 25 among U.S. public universities

MinesNewsRoomColorado School of Mines was ranked 23rd among public colleges in the United States and 20th in the West in the 2019 list of America’s top universities by Forbes. The Forbes rankings are based on alumni salary, student satisfaction, student debt, on-time graduation rate and academic success, the last of which rewards schools for student PhD attainment, prestigious scholarships and fellowships. Forbes also considers what it calls American Leaders, which is based on the magazine’s database of successful people, including billionaires and leaders in public service and private enterprise. Forbes highlighted that Mines is home to the largest collegiate chapter of the Society of Women Engineers and the Geology Museum, which houses a moon rock from Apollo 17. Forbes also noted that 88 percent of Mines alumni land a job in their industry or pursue graduate degrees and have an average starting salary of $67,229. Mines was ranked 94th overall on the Forbes list. Among public colleges, it ranked behind only the U.S. Air Force Academy within the state of Colorado. CONTACTJoe DelNero, Digital Media and Communications Manager, Communications and Marketing | 303-273-3326 | jdelnero@mines.eduEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273- 3361 | erusch@mines.edu

Read More -

6 years ago

Lunar test bed a playground for emerging space technology

MinesNewsRoomWhat does a lunar test bed look like? For many of us, probably a bit like a great big sandbox — if that sandbox were filled not with play sand but finely ground basaltic cinders meant to simulate the dusty regolith that covers the surface of the Moon. For Christopher Dreyer, research assistant professor in Colorado School of Mines’ Space Resources Program, though, it looks like the future. “Fifty years after Apollo 11, plans are being made to return to the Moon. The way we will return and stay is by the use of resources on the Moon,” Dreyer said. Almost 50 years to the day since astronauts Neil Armstrong and Buzz Aldrin collected the first geologic samples from the lunar surface, we’re tackling a few questions about the new Mines Lunar Testing Facility and how it fits into the future of lunar exploration. What is regolith, really? Simply put, it’s Moon dirt. The mix of powdery dust, broken rock and other materials forms the top layer of the lunar surface. “There are two types of lunar surfaces — one is called mare and the other one is called highlands,” Dreyer said. “The Mines test bed simulates the mare regions, or the Earth-facing dark areas of the Moon.” How is regolith simulated here on Earth? Over six Apollo missions, astronauts brought back to Earth about 842 pounds of lunar rocks, core samples, pebbles, sand and dust. From those samples, scientists have since developed a number of simulants that roughly match the chemical composition, mineralogy, particle size, distribution and engineering properties of the real deal, for use in experiments both big and small. Mines went to Arizona’s Merriam Crater to source the material for its lunar simulant, the same location NASA has used in the past. Mines researchers purchased 20 tons of basaltic cinders mined from the volcanic ash deposit, for use in the test bed and other specific experiments. The cinders then had to be milled down from 8 millimeters in diameter to about 150-200 microns to better approximate the Moon’s dusty top layer. That work was done on campus at the Earth Mechanics Institute, where the test bed also resides. “NASA has test beds all over, at Kennedy, JPL, Marshall, Johnson Space Center, to test robotics, the mechanics of traversing a surface like this, drilling into it, excavation,” Dreyer said. “Our thought was, why can’t we be the university that has a test bed, too?” The test bed itself is roughly 6 feet by 12 feet in size, with about a foot and a half of material. Beneath the fine top layer are the larger 8-milimeter cinders. “The lunar surface isn’t just the fine stuff,” Dreyer said. “"There are rock fragments and layering of the subsurface. Depressions represent impact craters — if we were to turn it into a real lunar impact crater, it would have blown-out material from the impact and some of the material below would be glassy. Building a test bed is about getting the right simulant but also about creating a right simulated environment.” Who is the test bed for? Dreyer envisions three main user groups for the facility: faculty working on space resources research, student groups preparing for competitions such as the NASA Mars Ice Challenge and small businesses looking to test emerging technology. “Today, small businesses do not have a location where they can test their lunar technology. It takes time and investment to build their own test bed, learn how to make a good lunar simulant and keep it replenished,” he said. Companies have already started taking Dreyer up on the offer. For Lunar Outpost, a Colorado-based aerospace startup, having access to the test bed has been crucial to the development of their lunar rover, MAPP, said CEO Justin Cyrus MS ‘16. “The high-quality lunar regolith simulant is a differentiator that most other facilities cannot match,” said Cyrus, who is also a PhD student in the Space Resources Program at Mines. “That along with access to other crucial facilities at Colorado School of Mines Center for Space Resources, including TVAC and cryochambers, and the storied expertise of the faculty and researchers, makes the new Lunar Testing Facility truly a valuable asset for the Colorado aerospace community and the aerospace community as a whole.” What’s the future? In two words: space resources. Those resources could include the water trapped in the Moon’s permanently shadowed regions — capable of being made into rocket propellant — minerals, metals or even solar energy. Before they can be extracted and used in space, though, lunar rovers, lunar drills and more will need to be developed and tested here on Earth. Dreyer and Angel Abbud-Madrid, director of the Center for Space Resources at Mines, for one, are part of a project recently funded by NASA to develop lunar sample acquisition technology. They will be adapting the penetrometer work done by recent Mines PhD graduate Jared Atkinson to be used on a MAXAR robotic arm to make measurements of the lunar surface. Improvements to the Mines test bed are on the horizon, too. Dreyer said he would love to someday get the Mines facility up to the same level as NASA’s Swamp Works at Kennedy Space Center. “At Swamp Works, they have a large bed, probably 10 times ours, and it’s in a fully enclosed room ventilated with air scrubbers. They work in there only in full bunny suits and masks. It’s a very fine regolith — much finer than what we’re using right now — and it creates a lot of dust when you work with it,” Dreyer said. “We’re not there yet, but this is a start.” CONTACTEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273-3361 | erusch@mines.eduMark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu

Read More -

6 years ago

Lunar test bed a playground for emerging space technology

MinesNewsRoomWhat does a lunar test bed look like? For many of us, probably a bit like a great big sandbox — if that sandbox were filled not with play sand but finely ground basaltic cinders meant to simulate the dusty regolith that covers the surface of the Moon. For Christopher Dreyer, research assistant professor in Colorado School of Mines’ Space Resources Program, though, it looks like the future. “Fifty years after Apollo 11, plans are being made to return to the Moon. The way we will return and stay is by the use of resources on the Moon,” Dreyer said. Almost 50 years to the day since astronauts Neil Armstrong and Buzz Aldrin collected the first geologic samples from the lunar surface, we’re tackling a few questions about the new Mines Lunar Testing Facility and how it fits into the future of lunar exploration. What is regolith, really? Simply put, it’s Moon dirt. The mix of powdery dust, broken rock and other materials forms the top layer of the lunar surface. “There are two types of lunar surfaces — one is called mare and the other one is called highlands,” Dreyer said. “The Mines test bed simulates the mare regions, or the Earth-facing dark areas of the Moon.” How is regolith simulated here on Earth? Over six Apollo missions, astronauts brought back to Earth about 842 pounds of lunar rocks, core samples, pebbles, sand and dust. From those samples, scientists have since developed a number of simulants that roughly match the chemical composition, mineralogy, particle size, distribution and engineering properties of the real deal, for use in experiments both big and small. Mines went to Arizona’s Merriam Crater to source the material for its lunar simulant, the same location NASA has used in the past. Mines researchers purchased 20 tons of basaltic cinders mined from the volcanic ash deposit, for use in the test bed and other specific experiments. The cinders then had to be milled down from 8 millimeters in diameter to about 150-200 microns to better approximate the Moon’s dusty top layer. That work was done on campus at the Earth Mechanics Institute, where the test bed also resides. “NASA has test beds all over, at Kennedy, JPL, Marshall, Johnson Space Center, to test robotics, the mechanics of traversing a surface like this, drilling into it, excavation,” Dreyer said. “Our thought was, why can’t we be the university that has a test bed, too?” The test bed itself is roughly 6 feet by 12 feet in size, with about a foot and a half of material. Beneath the fine top layer are the larger 8-milimeter cinders. “The lunar surface isn’t just the fine stuff,” Dreyer said. “"There are rock fragments and layering of the subsurface. Depressions represent impact craters — if we were to turn it into a real lunar impact crater, it would have blown-out material from the impact and some of the material below would be glassy. Building a test bed is about getting the right simulant but also about creating a right simulated environment.” Who is the test bed for? Dreyer envisions three main user groups for the facility: faculty working on space resources research, student groups preparing for competitions such as the NASA Mars Ice Challenge and small businesses looking to test emerging technology. “Today, small businesses do not have a location where they can test their lunar technology. It takes time and investment to build their own test bed, learn how to make a good lunar simulant and keep it replenished,” he said. Companies have already started taking Dreyer up on the offer. For Lunar Outpost, a Colorado-based aerospace startup, having access to the test bed has been crucial to the development of their lunar rover, MAPP, said CEO Justin Cyrus MS ‘16. “The high-quality lunar regolith simulant is a differentiator that most other facilities cannot match,” said Cyrus, who is also a PhD student in the Space Resources Program at Mines. “That along with access to other crucial facilities at Colorado School of Mines Center for Space Resources, including TVAC and cryochambers, and the storied expertise of the faculty and researchers, makes the new Lunar Testing Facility truly a valuable asset for the Colorado aerospace community and the aerospace community as a whole.” What’s the future? In two words: space resources. Those resources could include the water trapped in the Moon’s permanently shadowed regions — capable of being made into rocket propellant — minerals, metals or even solar energy. Before they can be extracted and used in space, though, lunar rovers, lunar drills and more will need to be developed and tested here on Earth. Dreyer and Angel Abbud-Madrid, director of the Center for Space Resources at Mines, for one, are part of a project recently funded by NASA to develop lunar sample acquisition technology. They will be adapting the penetrometer work done by recent Mines PhD graduate Jared Atkinson to be used on a MAXAR robotic arm to make measurements of the lunar surface. Improvements to the Mines test bed are on the horizon, too. Dreyer said he would love to someday get the Mines facility up to the same level as NASA’s Swamp Works at Kennedy Space Center. “At Swamp Works, they have a large bed, probably 10 times ours, and it’s in a fully enclosed room ventilated with air scrubbers. They work in there only in full bunny suits and masks. It’s a very fine regolith — much finer than what we’re using right now — and it creates a lot of dust when you work with it,” Dreyer said. “We’re not there yet, but this is a start.” CONTACTEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273-3361 | erusch@mines.eduMark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu

Read More -

6 years ago

Apollopalooza to feature talks from two Mines professors

MinesNewsRoomTwo Colorado School of Mines professors are among the Apollo-era legends, astronauts, business leaders, innovators and thought leaders who will be speaking at Apollopalooza, Colorado’s weeklong celebration of the 50th anniversary of the Apollo 11 Moon landing and the future of space exploration. Hosted at Wings Over the Rockies in Denver, the July 13-20 celebration will feature more than 50 public panels, workshops, lectures, movie screenings and more, culminating in a special screening party of the Apollo 11 footage 50 years later to the minute—or 8:56 p.m., July 20 MT, to be exact. VIP speakers include Apollo 11 flight director Gene Kranz and Apollo 17 astronaut and U.S. Sen. Harrison Schmitt. George Sowers, professor of practice in the space resources graduate program at Mines, will give the July 19 keynote presentation at 1 p.m. in the Main Hangar. His talk, “Mining the Moon for Fun and Profit,” will focus on what could be the first economically viable lunar resource—the ice at the Moon’s poles, processed into rocket fuel. Richard Palin, assistant professor of geology and geological engineering, will also speak July 19 on the geology and geological history of the Moon. His presentation, focused on the current state of knowledge and future directions for research that could pave the way toward gaining a formative understanding of the Earth-Moon system, will begin at 2:15 p.m. in the Harrison Ford Theater. Both of the Mines professors’ lectures are included in the cost of a daily or weekly pass for the event. For more information or to buy tickets, go to wingsmuseum.org/events/apollo. CONTACTEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273-3361 | erusch@mines.eduMark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu APOLLO 11 PHOTO (Courtesy of NASA) -- Astronaut Edwin E. Aldrin Jr., lunar module pilot of the first lunar landing mission, poses for a photograph beside the deployed United States flag during Apollo 11 extravehicular activity (EVA) on the lunar surface on July 20,1969. The Lunar Module (LM) is on the left, and the footprints of the astronauts are clearly visible in the soil of the moon. Astronaut Neil A. Armstrong, commander, took this picture with a 70mm Hasselblad lunar surface camera. While astronauts Armstrong and Aldrin descended in the LM the "Eagle" to explore the Sea of Tranquility region of the moon, astronaut Michael Collins, command module pilot, remained with the Command and Service Modules (CSM) "Columbia" in lunar orbit.

Read More -

6 years ago

Apollopalooza to feature talks from two Mines professors

MinesNewsRoomTwo Colorado School of Mines professors are among the Apollo-era legends, astronauts, business leaders, innovators and thought leaders who will be speaking at Apollopalooza, Colorado’s weeklong celebration of the 50th anniversary of the Apollo 11 Moon landing and the future of space exploration. Hosted at Wings Over the Rockies in Denver, the July 13-20 celebration will feature more than 50 public panels, workshops, lectures, movie screenings and more, culminating in a special screening party of the Apollo 11 footage 50 years later to the minute—or 8:56 p.m., July 20 MT, to be exact. VIP speakers include Apollo 11 flight director Gene Kranz and Apollo 17 astronaut and U.S. Sen. Harrison Schmitt. George Sowers, professor of practice in the space resources graduate program at Mines, will give the July 19 keynote presentation at 1 p.m. in the Main Hangar. His talk, “Mining the Moon for Fun and Profit,” will focus on what could be the first economically viable lunar resource—the ice at the Moon’s poles, processed into rocket fuel. Richard Palin, assistant professor of geology and geological engineering, will also speak July 19 on the geology and geological history of the Moon. His presentation, focused on the current state of knowledge and future directions for research that could pave the way toward gaining a formative understanding of the Earth-Moon system, will begin at 2:15 p.m. in the Harrison Ford Theater. Both of the Mines professors’ lectures are included in the cost of a daily or weekly pass for the event. For more information or to buy tickets, go to wingsmuseum.org/events/apollo. APOLLO 11 PHOTO (Courtesy of NASA) -- Astronaut Edwin E. Aldrin Jr., lunar module pilot of the first lunar landing mission, poses for a photograph beside the deployed United States flag during Apollo 11 extravehicular activity (EVA) on the lunar surface on July 20,1969. The Lunar Module (LM) is on the left, and the footprints of the astronauts are clearly visible in the soil of the moon. Astronaut Neil A. Armstrong, commander, took this picture with a 70mm Hasselblad lunar surface camera. While astronauts Armstrong and Aldrin descended in the LM the "Eagle" to explore the Sea of Tranquility region of the moon, astronaut Michael Collins, command module pilot, remained with the Command and Service Modules (CSM) "Columbia" in lunar orbit. CONTACTEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273-3361 | erusch@mines.eduMark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu

Read More - 6 years ago

-

6 years ago

Mines celebrates Spring 2019 undergrad commencement

MinesNewsRoomColorado School of Mines celebrated its Spring 2019 Undergraduate Commencement on May 10, conferring a total of 932 bachelor’s degrees during three ceremonies at Lockridge Arena. Kiewit CEO Bruce Grewcock ’76 – one of the foremost leaders shaping our nation’s infrastructure – gave the keynote address during the ceremony. The Spring 2019 Outstanding Graduating Seniors, each representing a different academic major, were also honored for their scholastic achievement and involvement in departmental and school activities: Ashlyn Hohenshelt, Mining Engineering Hohenshelt, from Rockwall, Texas, will attend graduate school in the Mineral and Energy Economics program at Mines. Favorite Mines memory: “My favorite Mines memory will always be E-Days. From the cardboard boat race, field day, ore cart pull and the fireworks, I have enjoyed each and every event.” Jared Phillips, Civil Engineering Phillips, from Monte Vista, Colorado, plans to work and go to graduate school for a master’s degree in structural engineering. Favorite Mines memory: “Meeting new people and learning new things.” Evelyn Lundeen, Environmental Engineering Lundeen, from Gig Harbor, Washington, will join the environmental consulting firm Maul Foster & Alongi as a staff engineer in Seattle. Favorite Mines memory: “My favorite memory at Mines was participating in the cardboard boat race with my water polo teammates during my sophomore year. Our team (the Aquaholics) won best engineered.” Christina Breeze, Metallurgical and Materials Engineering Breeze, from Cherry Hills Village, Colorado, will attend the University of Wisconsin-Madison to attain a Master of Science in medical physics. She hopes to apply both her background in materials engineering and future in medical physics to pioneer advancements in medical technologies. Favorite Mines memory: “I will never forget the fun times I had with the adventure leadership community during my freshman year.” Caroline Fuschino, Electrical Engineering Fuschino, from Highlands Ranch, Colorado, has accepted a job with Texas Instruments as a product marketing engineer, where she will design promotional materials for semiconductor chips, monitor sales and determine how to grow profits. Favorite Mines memory: “My favorite memory was studying abroad in Rome. I got to experience local customs, eat incredible food and travel almost every weekend.” Aaron Engers, Geological Engineering Engers, from Arvada, Colorado, plans to complete a master’s degree in hydrology at Mines before pursuing a job as a hydrogeologist. Favorite Mines memory: “Geology and Geological Engineering Field Camp was a blast.” Daniel Langemann, Chemical Engineering Langemann, from Littleton, Colorado, plans to travel in southwest Europe before beginning engineering work with Noble Energy in northern Colorado. Favorite Mines memory: “My favorite memory was during a fall break trip to Vietnam with another Mines student. During our journey through a natural reserve, we zipped around towering limestone karsts on our motorbikes under a full moon.” Caelyn Rittenhouse, Chemical and Biological Engineering Rittenhouse, from Elizabeth, Colorado, will stay at Mines to complete a master’s degree in engineering and technology management, after which she hopes to work in the renewable energy or medical technology field. Favorite Mines memory: “In fall 2017, the women’s rugby team won our league for the first time in team history and went to the Sweet Sixteen in Chicago. We ended the season ranked fourth in Division II.” Sevy Swift, Mechanical Engineering Swift, from Golden, Colorado, is interviewing with hardware startups. Favorite Mines memory: “I love Celebration of Mines. This event brings together students from all Mines clubs and organizations to share why first-year students should join their community and believe in something new.” Addison Kenyon, Petroleum Engineering Kenyon, from Arvada, Colorado, is getting married in June before starting a position with Encana in Denver as a field engineer out of the company’s Eagle Ford asset. Favorite Mines memory: “Although it was a challenging experience at the time, Field Session 2 out in Massadona, Colorado. This trip solidified so many of my friendships with other students and definitely lived up to the phrase, ‘the most fun I never want to have again.’” Michael Morphew, Geophysics Morphew, from Woodstock, Illinois, will join ExxonMobil’s upstream research company in Houston, where his work will involve automatic seismic interpretation using machine learning. Favorite Mines memory: “My favorite Mines memory is the geophysics field camp. Our geophysics class worked hard for two weeks, and I’m really proud of what we accomplished both in the field and in the lab.” Kate Bubar, Computational and Applied Mathematics Bubar, from Redmond, Washington, will pursue a PhD in applied math with a certificate in interdisciplinary quantitative biology at the University of Colorado Boulder. She hopes to work in mathematical epidemiology to model disease spread and help inform public health policy. Favorite Mines memory: “My favorite memory is Celebration of Mines each fall, because everyone is happy and excited to share what they’re passionate about outside of academics. Through different clubs, I’ve made amazing friends and tried different activities I never expected to participate in, like kayaking Clear Creek and paddleboard yoga.” Danielle Barna, Statistics Barna, from Idaho Falls, Idaho, will attend graduate school at Mines. Favorite Mines memory: “Eating ice cream up at the M at 2 a.m.” Jack Larrabee, Chemistry Larrabee, from Glen Ellyn, Illinois, will pursue his PhD in nuclear engineering at University of California, Berkeley. Favorite Mines memory: “In spring 2018, the school funded my travel to the American Chemical Society National Meeting in New Orleans. It was an amazing experience, both for the conference and the travel itself.” Galen Vincent, Physics Vincent, from Tucson, Arizona, will stay at Mines for another year to pursue a master’s degree in statistics. Favorite Mines memory: “My favorite memory is when my team won the intramural volleyball championship or when my friends and I would spend entire delirious weekends of junior year working on projects.” Kristin Farris, Computer Science Farris, from Littleton, Colorado, will be pursuing her love of math as a graduate student in the computational and applied mathematics master’s program at Mines. Favorite Mines memory: “My favorite Mines memory each year is always the ore cart pull. It is such a unique tradition that always kicks off E-Days with a ton of energy. I also love that it is led by everyone’s favorite burro, Blaster.” Alexander Adams, Economics and Business Adams, from Greeley, Colorado, will join Blue Steel Real Estate as CFO, managing the Greeley company’s finances, evaluating future projects and helping expand the business. Favorite Mines memory: “My favorite Mines memory is attending my first peer mentoring training. I got to meet awesome people, learn valuable leadership skills and have lots of fun.” ADDITIONAL UNDERGRADUATE AWARDS AND RECOGNITIONS: The Alan Kissock Award is awarded to graduating seniors in metallurgical and materials engineering, acknowledging creativity in metallurgy: Stuart Shirley (creative effort in outreach); Itamar Brill (creative effort in outreach); Kelsey Cannon (creative effort in the Materials Advantage Chapter); and Brionna Dumalo (creative effort in the Materials Advantage Chapter) The American Institute of Chemists Award honors outstanding seniors, post-baccalaureate and postdoctoral students majoring in chemistry, chemical engineering or biochemistry. The awards are given in recognition of a demonstrated ability, leadership and professional promise. Candidates are chosen and nominated by their faculty members: Marina Tobey The Brunton Award in Geology is awarded in recognition of the highest scholastic achievement and interest in and enthusiasm for the science of geology: Larkin Martini The Cecil H. Green Award is given to the graduating senior in geophysical engineering who, in the opinion of the Department of Geophysics, has the highest attainment in the combination of scholastic achievement, personality and integrity: Alicia Downard The Charles N. Bell, 1906, Award, provided for by Mr. Bell, is a Brunton transit, awarded in mining for completing a course in mining and showing the most progress in schoolwork during the entire period for which the course is given: William Fraser The Clark B. Carpenter Award is presented to the graduating seniors in mining or metallurgy who, in the opinion of the senior students in mining and metallurgy and the professors in charge of the respective departments, is the most deserving of this award: Kinsley Costner and Zoey Huey The Colorado Engineering Council Awards are presented for excellence in scholarship, high integrity and general engineering ability: Chloe Archuleta, Christina Breeze and Jordan Umrysh Distinguished Military Graduate Award: Mitchell White Dwight D. Eisenhower Award: Mitchell White The Faculty Choice Award in Computer Science is given to a top graduating senior who helped improve computer science at Mines: Bethel Tessema and Samuel Reinehr The George R. Pickett Memorial Award is presented on the basis of demonstrated interest and accomplishments in the study of borehole geophysics: Zachery Huxel The George T. Merideth Award, established in 2012 by Keith A. ’52 and Mary Ann Kvenvolden to carry forward the legacy of former Mines Geophysics Professor George T. Merideth, is presented to outstanding graduating geophysics students who have demonstrated academic excellence, community involvement and potential for leadership in earth science engineering: Daniel Ciraula The H.G. Washburn Award is presented in mining for good scholastic record and active participation in athletics: Alesander Draeker H.L. Hazen Prize in Process Metallurgy: Chase Bailey The Harrison L. Hays, 1931, Award is presented in chemical and petroleum refining for demonstrating scholarship, personality and integrity of character and the general potentialities of a successful industrial career: Kathleen Whalen and Jordan Umrysh The Henry W. Kaanta, 1915, Award is presented for the outstanding paper on a laboratory procedure or experimental process written by a graduating senior majoring in extractive metallurgy or mineral processing: Cameron Baker The Honorable D.W. Brunton Award, provided for by Mr. Brunton, is awarded for meritorious work in mining: Stephen Simmons Hutchinson Award: Larkin Martini The John C. Hollister Award is presented to the most deserving student in geophysics and is not based solely on academic performance: Sarah Alhumaidan The Mary & Charles Cavanaugh Award, presented in metallurgy, is determined by scholarship, professional activity and participation in school activities: Victoria Avance The McIver-Metallurgical and Materials Engineering Faculty Award is presented by the faculty of the department to the graduating senior who, by participation in and contribution to campus life and by academic achievement, has demonstrated those characteristics of a well-rounded graduate that Mines aspires to develop in its students: Spencer Randell The Neal J. Harr Memorial Outstanding Student Award, provided by the Rocky Mountain Association of Geologists, is presented for scholastic excellence in the study of geology with the aim of encouraging future endeavors in the earth sciences: Tatjana Scherschel The Old Timers’ Club Award is presented to the graduating senior who, in the opinion of the Department of Mining Engineering, has shown high academic standing in coal mining engineering and potential for the coal industry: Stela Cayatte The Outstanding Senior Research Award in Chemistry is awarded to students who demonstrate superior performance and creativity in undergraduate research: Jack Larrabee and Dana Portlock The Outstanding Senior Research Award in Computer Science is awarded to a student who demonstrates superior performance and creativity in undergraduate research: Kai Nichols The Outstanding Student Service Award is presented by the Division of Student Life to the student who, during their tenure at Mines, outside and above their academic role, vigorously participated in activities or projects for the greater benefit of their peers and community to promote excellence and well-being: Boston Ludlow and Sevy Swift The Pearson Potential Award is given to students in the Department of Chemical and Biological Engineering who have shown emerging leadership and engineering potential in hands-on challenges such as summer field session: Logan Weinman and Andrew Nagy Phillip R. Romig Award in Geophysics: Aspen Davis and Sean R. Smith The Physics Faculty Distinguished Graduate Award is presented by the faculty of the department to graduating seniors with exceptionally high academic achievement in physics: William Daniels and Martin Kuhnel The President’s Senior Scholar Athlete Award is presented to one graduating female and male athlete with a cumulative grade point average of 3.0 or higher, has lettered in a sport during their senior year and has demonstrated leadership qualities of an exemplary student-athlete: Megan Wenham and Joseph Popp The Robert A. Baxter Award is presented for meritorious work in chemistry: Dakota Isaak The Selim Memorial Scholarship is presented by the faculty of the Department of Chemical and Biological Engineering to a graduating student who promises great success in graduate school: Grace Anderson and Brandon Bakka The William D. Waltman Award is presented to the graduating seniors who have consistently demonstrated the utmost integrity, scholarship and citizenship in and outside of the classroom throughout their collegiate career: Bethel Tessema and Grace Anderson MILITARY COMMISSIONS The following students will be commissioned as second lieutenants in the United States Air Force: Brandon M. Hall, Computational and Applied Mathematics Adam J. Nelson, Computer Science Ian R. Oberndorfer, Mechanical Engineering The following student will be commissioned as a second lieutenant in the United States Army: Mitchell I. White, Mechanical Engineering MORE COMMENCEMENT PHOTOS: View photos from the graduate and undergraduate commencement ceremonies Order professional photographs of graduates from the ceremony at gradimages.com. CONTACTEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273-3361 | erusch@mines.eduMark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu

Read More -

6 years ago

-

6 years ago

Bruce Grewcock named Spring 2019 commencement speaker

MinesNewsRoomBruce Grewcock, chairman and CEO of Peter Kiewit Sons' Inc. and a graduate of Colorado School of Mines, will give the keynote address at his alma mater's Spring 2019 Undergraduate Commencement ceremony on Friday, May 10. A Fortune 500 company and the fifth-largest general contractor in the United States, Kiewit provides construction and engineering services to a variety of markets including building, mining, oil, gas and chemical, power, transportation, industrial and water. Grewcock has led the Omaha-based employee-owned company since 2005. "Bruce is one of the foremost leaders in industry. He has had an amazing career and from his leadership position at Kiewit is shaping our nation's infrastructure," said Mines President Paul C. Johnson. "He has always acknowledged the impact that Mines has had on his life and how a strong work ethic, practical skills, technical depth, humility and analytical thinking are a great foundation for professional and personal success. Bruce has for many years been a valued advisor to Mines - he challenges us to aspire to greatness and also supports the efforts needed to achieve that goal. We are very fortunate to count him as one of our alumni and one of Mines' most dedicated and passionate supporters." Grewcock graduated from Mines in 1976 with a bachelor's degree in mining engineering. He started his career with Kiewit in 1982 as a chief engineer at Black Butte Mine in Wyoming, and was subsequently promoted to vice president and operations manager. In 1992, Grewcock became president of Kiewit Mining Group, where his responsibilities expanded to include Kiewit's construction materials and quarries operations. In 1994, he was given the additional responsibility of division manager for construction operations. That same year he was elected to and still maintains a position on the Kiewit board of directors. In 2000, Grewcock became president and chief operating officer of Kiewit. He assumed the role of chief executive officer in 2005, becoming the seventh executive to lead the company, and in 2013, he became chairman of the board of directors. Since Grewcock took over as CEO, Kiewit has earned record levels of revenue, increasing from $4.1 billion in 2005 to $8.6 billion in 2016. Kiewit has also been named to Fortune Magazine's 100 Best Companies to Work For list in the United States and has been recognized as one of the best workplaces in Canada. A longtime supporter of his alma mater, Grewcock is one of Mines' top individual donors and serves on the executive committee of the Colorado School of Mines Foundation Board of Governors. He was honored with the Mines Distinguished Achievement Medal in 1999. In 2012, Grewcock made a large financial investment - a gift of several million dollars - to establish the university's center for underground construction and tunneling (UC&T) and support the program's faculty. In 2018, he invested in the growth of the UC&T program again and provided seed funding for an industry fellowship matching program and graduate student recruiting position. In addition to his degree from Mines, Grewcock also attended the Stanford Graduate School of Business Executives program in 1989. He is a member of Business Roundtable, an association of CEOs of leading U.S. companies. A leader in the community, Grewcock serves as a director of Nebraska Medicine and Creighton University. He received the Golden Beaver award in management in 2016 and the Moles Award in 2013 for his distinguished career in the construction industry. "It's such an exciting time to be stepping into this fast-changing industry. I've seen some dramatic changes during my career, but I'm almost jealous of the incredible journey that lies before the graduating class of 2019. I know firsthand how well Colorado School of Mines prepares its students for that journey and, as a Mines alum, I'm incredibly proud of the education and research it's doing to help society navigate toward a better standard of living," Grewcock said. The Colorado School of Mines Spring 2019 Undergraduate Commencement will take place at 9 a.m. Friday, May 10, at Marv Kay Stadium at the Harold M. and Patricia M. Korell Athletics Center. A live webcast will also be available on the Mines YouTube channel. For more information, go to commencement.mines.edu. CONTACTEmilie Rusch, Public Information Specialist, Communications and Marketing | 303-273-3361 | erusch@mines.eduMark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu

Read More